Installations

Alucushion®/Bubblefoil® can be installed under steel roofing (Industrial Application) and under roof tiles (Domestic Application).

Step 1

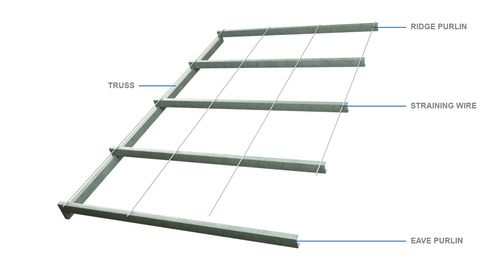

Industrial Application 1

Fix PVC coated straining wire from the top apex purlin, over intermediate purlins to the bottom eave purlin at 383 mm centers – first straining wire to be fixed 50 mm away from gable end. Evenly tension all wire ensuring that cut ends face downwards.

Step 2

Industrial Application 2

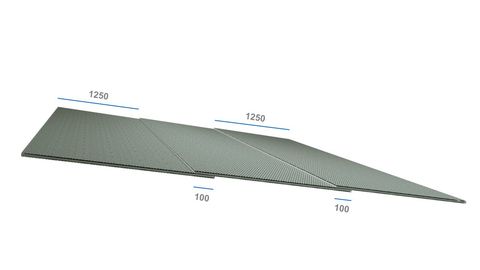

Lay Alucushion® / Bubblefoil® FR over the straining wires ensuring that it is squared off. Fix to apex purlin using double-sided tape. Evenly tension material and fix to eave purlin again using double-side tape.

Step 3

Industrial Application 3

All subsequent layers of Alucushion® FR to be fixed as above with a 100 mm overlap over the previous sheet.

Straining wires must be positioned at the center of the overlaps i.e. not more than 50 mm from the sheet edges.Lay roof sheeting as soon as possible after the fixing of Alucushion® FR.

Straining wires must be positioned at the center of the overlaps i.e. not more than 50 mm from the sheet edges.Lay roof sheeting as soon as possible after the fixing of Alucushion® FR.

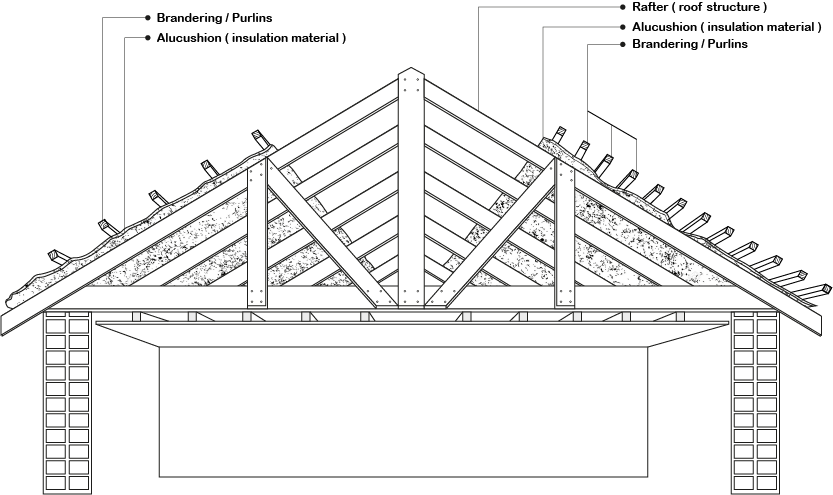

Domestic Application

Steps

Domestic Application

- Because of Alucushion® / Bubblefoil® FR’s tensile strength and ease of handling, there are various application options available depending on the particular roofing material and / or design, construction method and project requirements (i.e. thermal control, waterproofing, ceiling substitution etc.)

- The most common method is that illustrated in the sketch i.e. stapled with industrial staples to top of rafters before fixing of brandering. Material is laid horizontally (between gable ends) commencing at the eaves and ensuring that subsequent sheets overlap the previous sheet. With this method the Alucushion® acts as both insulation and a waterproofing membrane.

- Where the roofing is in sheet form the industrial method of installation is normally used with or without straining wires.

- An alternative method is to staple Alucushion® FR to the bottom of the roof trusses prior to the fixing of the ceiling brandering.